- Why Aluminum?

- Pros of Aluminum Siding

- Cons

- Alternatives

- What are the Top Brands of Aluminum Siding?

- Can I Paint Aluminum Siding?

- Thicker Siding is More Durable

- What to Read Next

- Over to You

Aluminum siding was first offered for home construction in the 1930s as it was an affordable, durable and low-maintenance alternative to wood siding. The advent of WWII brought a temporary halt to its usage as siding, since all available aluminum was being used in the war effort. As soon as the war was over, this low-cost, lightweight siding was brought back into the market.

The energy crisis during the 1970s caused the price of raw materials to skyrocket – including raw aluminum. This triggered the research and development of alternative forms of home siding, including vinyl and stucco. Aluminum gradually lost ground in the ensuing decades due to the popularity of the lower cost vinyl, but still has its place in the market.

Why Aluminum?

Aluminum is dent-resistant, and insect-proof. Needless to say, metal is not flammable, so it is often preferred in regions where brush fires are common. Today’s metal panels don’t require much maintenance and occasional power washing is all that is needed.

The color is applied at the factory. Customers order the color they want from those offered, and the enamel provides a strong, long-lasting finish. The enamel finish on aluminum panels usually comes with a 15 to 25 year warranty covering fading or chalking. If you take good care of aluminum siding by keeping it clean and impacts to a minimum, it will last more than 50 years.

The metal can be stamped or molded with a wood grain pattern. Homeowners and builders will often create designs that combine sections of aluminum siding with other materials such as stone or masonry to provide a unique look.

While this is often the siding of choice for those wanting an industrial look, there are other ways to use it. For example, homeowners often elect to use use it for soffits and gables because of its durability. These components will never need to be painted, as the sun doesn’t shine on the underside of the eaves, and they will not get dented by hailstones or foot traffic.

The following guide will outline all of the pros and cons of aluminum siding:

Pros of Aluminum Siding

Some of the advantages of this type of metal siding are that it is:

Cost Effective

Aluminum is one of the cheapest siding materials available. You can expect to pay about $2.20 per sq. ft. for aluminum siding. The heaviest-gauge metal will cost about $5 per sq. ft. Total cost is $5 to $9 per square foot installed.

It is about cheaper than 80% of the other types of siding. It can also be completely recycled, and is often made at least partly of recycled materials.

Aluminum siding is lightweight which makes it easier to install, which saves you money on the cost of labor to install it. Contractors typically have to remove your existing siding in order to replace it with new siding, but under the right circumstances they can install heavy-gauge aluminum over your existing siding – lower the installation cost even further.

Low-Maintenance

All you need to do is rinse it off about once a year to make sure there is no debris lodged in seams or window sills. Once the enamel has faded (usually after 12 to 15 years) you’ll need to repaint it.

Energy Efficient

Unlike other forms of siding, aluminum is a good insulator, and the heavier aluminum provides more insulation than thinner gauge. Bare aluminum has an R-Value of .61. If you add insulation to the back of it, it provides an R-value of 2 to 5. It keeps heat out in the summer and keeps warmth in during the winter. As for insulation, metal does a better job than vinyl does – saving you on your utility bills.

Environmentally Friendly

Aluminum siding is considered a “green” siding product. It is 100% recyclable, so there is no need for it to ever go to a landfill. Some manufacturers produce only 100% recycled siding, while others use a significant amount of recycled materials in the production of their siding.

Waterproof & No Rust

If you live on the coast or in another humid region, aluminum is the perfect choice for you. It does not rust and will not absorb moisture the way wood does. It will not swell in humidity, nor will it dry out and shrink in the heat. The only mildew that will grow is on debris allowed to build up against the siding.

Variety

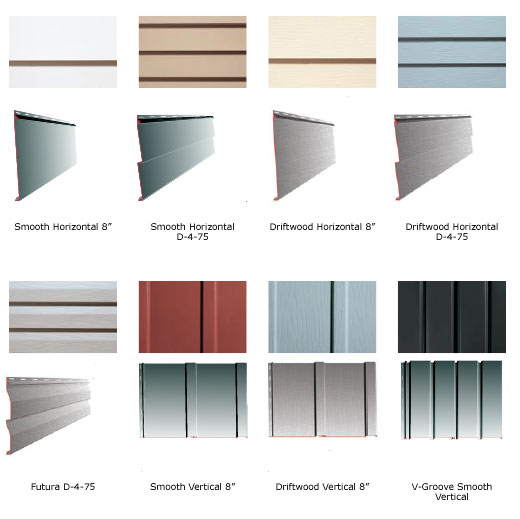

A number of different patterns and textures are available for aluminum panels – many imitating the look of wood siding. The panels can comes pre-painted in the baked-on color of your choice, or you can opt to paint the siding yourself.

While most people think of horizontal planks when picturing siding, this product is also available in vertical panels. This gives you the freedom to design any look you want to match your home’s architecture.

For a rustic ranch style or bungalow, you may want vertical panels in a board and batten design. This pattern can be ordered with reveals of double 4” and double 5” as well as single 10” and single 12.”

Insect Proof

Metal is insect proof. This single feature may make it the most popular siding choice in areas with infestations of carpenter ants and termites.

Fire-Resistant

It is non-flammable meaning it will not ignite, making it preferable for areas with frequent brush fires, since it will not feed fires. It also will not burn or melt. The enamel paint may become scorched, but can be cleaned and painted.

Since it does not burn, it does not emit dangerous fumes when it gets hot the way vinyl can. The fireproof nature of aluminum siding makes it a popular choice with insurance companies, which will often give homeowners a discount if they have this product on their home.

Durable

Most aluminum siding is manufactured from aluminum coil stock material which is often produced from recycled materials. The siding is coated with chemicals to prevent corrosion. The color is then baked on, with a final layer being imprinted with your choice of texture. This product is sturdy and not prone cracking with age, the way vinyl can.

If your aluminum panels are installed correctly and properly maintained, the siding can last 40 to 50 years. Compare this with vinyl that has a lifespan of about 30 to 40 years. If you live in a part of the country that has extreme temperatures, metal may be a better choice. It won’t crack and get brittle in the winter or sag and warp in extreme heat or flames.

Cons

Here are some of the downsides of aluminum siding:

Dents & Scratches Easily

Aluminum is a soft metal, so it is easy to work with on the job site. However, this also makes it more prone to scratches and dents.

If you live in an area with hailstorms or if there is heavy traffic around your house, you should expect to need more repairs to your metal siding. Children riding bicycles, playing football or baseball, or driveway hockey can lead to impact dents that are hard to remove.

Small dents are often repaired much the same way auto dents are repaired, and may need to be done professionally. The repairman will drill a small hole in the center of the dent and pull it out. Then they will fill and sand the hole and repaint the spot.

Repairs to metal siding are more difficult because once the colors have faded, they are hard to match. Vinyl also has this problem. Unlike vinyl, though, the color is a finish that is bonded to the metal rather than permeating the product. Therefore, after a severe blow, the paint may chip. A scratch on metal siding shows up more because the underlying primer shows through, whereas with vinyl, the color goes all the way through.

Heavier gauge metal is more resistant to dents.

Noises

Metal will expand and contract slightly with temperature changes. This can create a popping or ping noise. Very high winds can also produce these pinging sounds. In addition, rain and hail can sound loud on aluminum siding. Some homeowners are irritated by this, others like the sounds. Still others never notice.

Industrial Appearance

While the texturing of metal siding has improved drastically in the last decades, it still looks like metal. This is especially obvious when you stand close to the siding. Vinyl and fiber cement are able to imitate wood siding better than metal does. With its metallic appearance, it has a slightly industrial look.

Alternatives

Aluminum vs. Wood Siding

If you are dedicated to an authentic wood look for your home, then wood siding will be your choice. You will have a wider selection of profiles, such as clapboards, hand-cut shakes, and mass-produced shingles.

However, wood requires much more maintenance and is vulnerable to insects. Wood is often banned in some areas that have high instances of brush fires, and even high-grade cedar will rot. Metal has none of these problems. It doesn’t look like real wood, but it is low maintenance.

Aluminum vs. Vinyl Siding

While aluminum is quite affordable, vinyl is cheaper still. It is made of PVC and is available in more varieties of profiles. You can order Dutch lap, scalloped, standard, and vertical profiles, among others. It doesn’t dent, and if it gets a scratch it won’t show up because the color goes all the way through the product.

However, vinyl gets brittle as it ages and is prone to breaking and cracking. Vinyl is non-recyclable, too, so doesn’t rank as highly for being eco-friendly. Its lifespan is 30 to 40 years, much like metal, but it contains PVC which never breaks down in landfills.

What are the Top Brands of Aluminum Siding?

Some of the best manufacturers of aluminum siding are:

- Rollex

- Royal Building Products

- Mastic (formerly Alcoa)

- Revere

Alcoa may ring a bell – it was once the master of the aluminum siding market, but it is now owned my Mastic.

Can I Paint Aluminum Siding?

Yes, you can paint aluminum siding. In fact, manufacturers recommend that after a couple of decades, when the enamel has significantly faded, chipped, or crazed, that you should prep and paint your siding for better maintenance.

To paint metal, you should thoroughly prep it by removing all loose particles, creating a smooth, clean surface. Metal siding gets chalky, so acrylic enamels have been developed specifically to deal with the chalking problem.

Make sure the seams, joints, and window and door seals are properly caulked, the paint the siding. Each of the major paint companies makes enamel for use on metal siding. This paint has select binders in it to make it bond tightly to metal surfaces, even if there is oxidation.

Be sure to get paint specifically designated for metal siding, because these binding properties are not present in other types of paint. In addition, the binders will keep oxidation from coming to the surface of the new paint job. To get the best results with your new paint job, you should use spray-on paint.

Thicker Siding is More Durable

It may seem to go without saying, but thicker metal is stronger and more durable. The cheapest aluminum is .4” thick, or 40-gauge. This is lightweight, and often chosen by commercial home builders. This is the builders’ grade aluminum siding, and may dent and bend quite easily.

The industry standard is .44-gauge. However, if you are buying new siding for an existing structure, or are building a new home and need siding, you need to get .53-gauge. It costs more, but you get a stronger, more durable product. This heavyweight aluminum siding should last upwards of 35 years, maybe longer. It will have to be painted a couple of times during that lifetime.

With heavy-gauge aluminum siding, the greatest issue is the finish. It will have a good warranty, but after a couple of decades it will be pitted, cracked, and even chipped. This will require thorough cleaning and prep, then paint every now and then. While the appearance of the finish may decline, when properly maintained, aluminum siding will protect your home for many years.

What to Read Next

Over to You

What do you think of aluminum siding? Have you received a quote? Tell us about your experiences in the comment section.